Original link: https://mp.weixin.qq.com/s/bpUGBPIuGOrcCQZQJ1P9Lg

Driven by global environmental governance and the goal of "double carbon", plastic circular economy is facing unprecedented development opportunities. As a pioneer in this field, Guangxi Wuzhou Guolong renewable resources development Co., Ltd. (hereinafter referred to as "Guolong renewable") has successfully developed a new path of high-value plastic recycling integrating green, environmental protection, quality and science and technology for more than ten years.

Guojiawan, chairman of Guangxi Wuzhou Guolong regeneration

Strategic Transformation: industrial vision from real estate to circular economy

In 2012, the domestic plastic recycling industry was still in its infancy. Guojiawan, chairman of Guolong renewable, entered the industry from the real estate industry and the hotel industry. This decision is based on the in-depth investigation of Wuzhou's industrial environment: the traditional manufacturing industry is highly competitive and lacks high-tech talents. The imported renewable resources Park established in 2011 provides a policy window for us to pay attention to the development of renewable resources industry. "At that time, we found that the 'bottle to bottle' regeneration technology in Europe had matured and established a complete industrial chain from recycling, sorting to regeneration. In contrast, as a large plastic production and consumption country, China lags behind in this field. ”Guo recalled.

He further analyzed and pointed out: "China is still a big country in plastic application. The annual plastic consumption is huge, accounting for more than one third of the world's total output. This significant growth is due to the continuous progress of industry technology and the continuous expansion of market demand. However, the accompanying environmental challenges are equally severe - about 60million tons of waste plastic are produced every year in China, but the standardized recovery rate is less than 30%. A large amount of plastic waste enters landfills or the natural environment, exacerbating 'white pollution'. Faced with this challenge, various ministries and commissions have successively issued a series of policy documents on the recycling system of renewable resources. These policy signals indicate that the plastic recycling industry is about to usher in explosive growth."

At the international level, Mr. Guo noticed a significant trend: "some large international brand enterprises take the initiative to use recycled plastics in their products and take the initiative to undertake the responsibility of plastic recycling. This means that a two wheel driving pattern of 'policy promotion + market pull' is being formed worldwide. We judge that the waste plastic recycling market has great potential for future development."

It is precisely this precise grasp of the industrial development trend at home and abroad, as well as a deep understanding of the national strategic direction, that finally prompted Mr. Guo to make an important decision to comprehensively transform the recycled plastic industry. "This is not an impulse, but a strategic choice based on the systematic analysis of industrial laws, market trends and policy guidance," he concluded.

Therefore, since 2013, he has conducted two years of investigation and Research on domestic and foreign projects. With his R & D team, Mr. Guo has visited 26 countries, studied more than 50 cases, and made an in-depth analysis on the development direction and business model of recycled plastics; At the same time, an in-depth investigation was conducted on nearly a thousand domestic waste plastic recycling enterprises, combined with the characteristics, recycling mode and development of waste plastic in China. Established the strategic positioning of the closed-loop development of the whole industry chain business model, and the business model of high-value utilization and high-quality product development. With the improvement of the recycling system and the popularization of high-value utilization technology, the closed-loop development mode of the whole industrial chain of Guolong recycling has been rapidly formed, which promotes the high-quality development of China's plastic circular economy.

Technological innovation: the closed-loop development model of the whole industry chain and the construction of technical barriers

In the recycled plastic industry, good products rely on good processing equipment system. ”Guodong stressed, "we know that to realize the high-value utilization of waste plastics, we must build a complete process equipment chain. For this reason, Guolong regeneration has integrated the world's advanced production equipment in various links, such as crushing, cleaning, sorting, granulation, sheet production, thermoforming, etc., including the pet whole bottle crushing and cleaning line of Italian sorema, pet granulation production line of Austrian erema, German tomra photoelectric sorting equipment, SSP equipment of Swiss Buhler, r-PET sheet production line of SML and erema, and German Kiki.Efel hot forming equipment, cup making machine and other production equipment.

The technical capability of each module and unit of Guolong regeneration is at the international top level, and it is recognized as the champion in each field. After more than 12 years of production and R & D, Guolong regeneration has integrated more than a dozen recycled plastic manufacturing equipment in the world on the basis of absorbing the international top process technology and combining the quality characteristics of China's waste plastics, forming a production line with independent core technology in Guolong.

Through the production layout of the whole industry chain, Guolong renewable has mastered the core technology of recycled plastics and obtained a series of domestic and international certifications. At present, Guolong renewable has cooperated with the State Key Laboratory to undertake the contact challenge test of China's recycled pet food and achieved success; Guolong recycled PET has passed the FDA challenge test, becoming the only enterprise in the Asia Pacific region that has passed this test; Guolong recycling participated in the formulation of standards for recycled plastics in contact with food and became one of the drafting units of recycled PET standards. So far, Guolong regeneration has obtained 17 process equipment patents and 3 software copyrights. Pet, HDPE, PP and other products have been certified by the US FDA, the EU EFSA, GRS, ISCC, BRC carbon footprint, t Ü V recycling content, and the enterprise management has passed ISO14001, ISO09001, CE and other international certifications.

Guodong said that Guolong recycling focuses on the recycling of waste plastics and realizes the efficient recycling and reuse of waste plastics through advanced production processes and technologies. Guangxi Guolong renewable now can recycle 260000 tons of waste plastic every year and produce 200000 tons of recycled plastic products every year, which is equivalent to saving about 522000 tons of oil and 378000 tons of carbon emissions every year, greatly reducing environmental pollution and resource waste, truly achieving low-carbon, green and environmental protection, and making a positive contribution to protecting the earth's environment.

Guolong renewable continues to innovate low-carbon technologies, aims at advantageous products, builds a product carbon footprint blueprint step by step, accelerates the construction of a full process green manufacturing system, promotes energy conservation, carbon reduction and green development, and improves the "gold content" of development with the "green content" of the industry.

Future layout: national expansion and Industry Outlook

According to Mr. Guo, the whole society is actively supporting the development of recycled plastic industry from policies to resources. Guolong must lay a good foundation, better grasp the general direction, and create a leading recycled plastic circular economy industry in China.

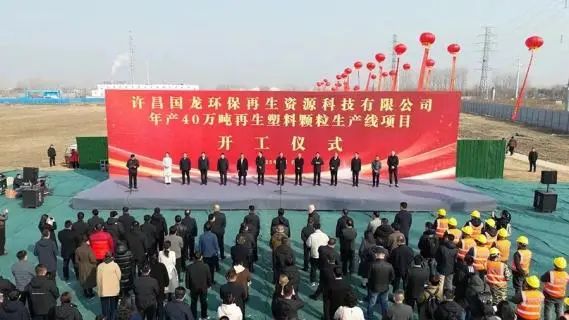

Guolong renewable's 400000 ton / year recycled plastic project in Xuchang, Henan Province was successfully started in February this year. It is expected to complete the construction of plants this year, and the project will be put into operation in October next year. The project covers an area of 160000 square meters (about 245 mu), with a total planned investment of RMB 1.5 billion. The project aims to recycle 600000 tons of waste plastic annually, and produce 100000 tons of food grade r-PET particles, 50000 tons of r-hdpe particles, 50000 tons of r-pp particles, 100000 tons of industrial grade r-hdpe particles, 50000 tons of r-ldpe particles and 50000 tons of r-pp particles every year. Superimposed on the production capacity of Wuzhou base, the overall production capacity of Guolong is expected to exceed 600000 tons, of which 280000 tons are food grade recycled particles. Gold content ".

Guolong regeneration is starting from Guangxi to start a new journey of national strategic layout. With the full production of the Guangxi plant, the company plans to gradually copy the mature closed-loop mode of the whole industrial chain to the Pearl River Delta, Yangtze River Delta, central China, North China, southwest and other key regions, and make every effort to build a leading recycled plastic enterprise with global competitiveness through the Trinity development path of "waste reduction, reuse and recycling".

The landing of Xuchang factory marks that Guolong regeneration development has entered a new stage, but this is only the beginning. In the interview, Mr. Guo stressed that "in the next 10 years, we will maintain our strategic focus and continue to cultivate the recycled plastic industry. This stage will be a golden development period with investment expansion as the main theme."

Conclusion

From cross-border real estate to circular economy, the ten-year exploration of Guolong regeneration has proved that green development is not a burden, but a new development opportunity. Through technological innovation and business model innovation, waste plastics can turn waste into treasure and realize the unification of economic value and environmental value.

"Our vision is to recycle every gram of plastic," said Guo. In the context of global plastic pollution control, the practice of Guolong regeneration not only provides a reference sample for the development of China's circular economy, but also contributes the wisdom and solutions of Chinese enterprises to global environmental governance.

With the in-depth promotion of the "double carbon" strategy, China's plastic circular economy is ushering in a golden period of development. The innovative enterprises represented by Guolong regeneration are riding the wind and waves in this blue ocean to create a new future of sustainable development.